Ahead of our time

for over

35 years.

As a refinery, we bear special responsibility for the environment, for our employees and for the people in the region. That is why we rely on state-of-the-art technology, intelligent processes and a strong team that gives its all every day.

We are one of the most energy-efficient refineries in Europe and are continuously working to further reduce our CO₂ emissions. Safety is always our top priority: we have our own fire brigade, comprehensive protection systems and clear procedures for emergencies.

For us, responsibility means making the right decisions today for tomorrow – economically, ecologically and socially.

Energy efficiency

is our strength.

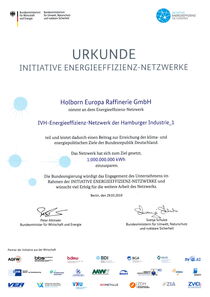

International comparison reveals that we are one of the most energy-efficient refineries in Europe, and we are proud of this. We don’t just want to remain in the top ten; we want to continue to improve and reduce our CO2 emissions even further. That is why we have implemented an energy management system and become certified to DIN EN 50001. We are also committed to exchanging experiences via various networks and initiatives.

The eternal quest

for even greater efficiency.

All refineries are very energy-intensive businesses. Our advantage: our refinery exhibits a higher degree of heat integration. For instance, we use heat exchangers to recover the heat from one product stream to heat another. We are then able to use a lower percentage of crude oil as a heating medium in comparison to other refineries, namely only around five per cent, for example, to operate our furnaces and production facilities.

We strive for the highest level of energy efficiency throughout the plant in order to save resources and protect the environment and the climate. Consuming less energy also reduces our energy costs – and at a refinery these are considerable. Even the smallest amount of energy saved reduces our costs significantly – and thus strengthens our competitiveness.

We want to continue to improve our energy efficiency – because this means we keep our production costs low, remain internationally competitive, and thus contribute more to climate protection.

Eco?

Logical!

We spend up to a third of our total annual budget on protecting the environment. In the past we have invested in major projects on a regular basis and will continue to do so to do even more for environmental protection. Plans include an improvement of our water treatment plant and the installation of technical equipment for emissions monitoring.

Our environmental commitment pays off twice: Not only do we fulfill the requirements of the constantly developing national and European environmental laws, but we are also able to save money; for example, lower electricity consumption and CO2 emissions overall. Consuming less electrical power also reduces costs and enables us to keep our competitive edge and strengthen Hamburg as a refinery location.

Clean

Water

We use our multi-stage treatment plant to purify waste-water from refinery operations. Soil and ground water are protected by concrete basins around our facilities. Rainwater from these is directed via channels to the waste-water treatment plant where it is purified.

Clean

Air

Our refinery is a closed system. One example of this is our vapour recovery systems, which prevent pollutants from escaping into the environment when we load our products. We also constantly improve our production and exhaust systems to reduce emissions. In any case: all our emissions are continuously measured and monitored. We transmit the values in real time to the supervising authorities.

Clean

Soil

The refinery's subsoil used to be heavily contaminated, especially due to its destruction during the Second World War. We have worked extensively to redress these issues from the past ever since the company was founded.

By the way: All our emissions are continuously measured and monitored. We transmit the values to the supervisory authorities in real time.

Maximum effectiveness.

Maximum safety.

Safety comes first: our primary goal is to operate our facilities responsibly and safely. To this end, we have high safety standards and comply with all legally prescribed requirements in all areas.

Plant

safety

Numerous measuring devices and monitoring systems guarantee smooth daily operations. Several independent safety systems ensure that the plant is automatically brought back to a safe state in the event of an incident. One of these is our flare system, which can be seen on the image above.

Work

safety

We take the safety of employees - whether our own or that of partner companies - very seriously. That is why we ensure a safe working environment with numerous technical and organisational measures.

Plant

security

Anyone entering the refinery area will be registered at the main gate for the duration of their stay. In addition, they receive a safety briefing on the most important rules, from personal protection, the speed limit of 30 km / h to the handling of fire or mobile phones inside the refinery area.

Comes with its

own fire brigade.

Große Mengen entzündlicher Stoffe, hohe Temperaturen und Drücke: Eine Raffinerie ist ein Produktionsbetrieb mit erhöhtem Gefährdungspotenzial. Deswegen verfügen wir über eine anerkannte hauptberufliche Werkfeuerwehr mit speziell ausgebildeten Feuerwehrleuten. Sie ist rund um die Uhr in Bereitschaft und sorgt für Sicherheit in der Raffinerie.

Die Werkfeuerwehr kümmert sich auch um den vorbeugenden und abwehrenden Brandschutz sowie um die Versorgung verletzter oder erkrankter Personen. Das bedeutet z. B., dass die 17 hauptamtlichen Feuerwehrleute regelmäßig für alle Arten von Einsätzen trainieren. Sie nehmen an Spezialübungen teil oder bilden sich fort. Außerdem schulen sie die mehr als 130 Kollegen aus den Anlagen, die als nebenamtliche Feuerwehrleute im Ernstfall unterstützen.

Die Werkfeuerwehr wartet außerdem die Feuerlöscheinrichtungen – und das sind nicht wenige: Neben mehreren Feuerwehrfahrzeugen und Abrollbehältern verfügen wir über eine hochmoderne Ausrüstung sowie zusätzliches Spezialgerät, wie etwa mobile Pumpen und Großwerfer für die Bekämpfung von Tankbränden.

Our plant fire brigade works closely with the Hamburg Fire Brigade. We regularly conduct joint exercises, often on our premises or in our harbour basin. With our equipment and specialised apparatus, we occasionally support the public fire brigade outside the plant premises. For example, in January 2021, it assisted with a major fire in Wilhelmsburg.

water monitors

per minute

In an emergency,

we don't flare around.

Safety is our top priority. In cooperation with the authorities we protect our neighbours, our employees, and the environment. Despite all precautions and care, however, incidents cannot always be prevented. The alarm and emergency response plan coordinated with the authorities and the police is activated should there be an incident. Residents and the general population are warned by measures implemented by these authorities, for example via the local smart phone Katwarn app.

Information on the proper protocol and on potential hazards can be found on this website published by the Hamburg Chamber of Commerce.

If you have any questions, please feel free to contact our incident supervisor: Tel.: +49 (0)40 76 63 - 0

Not an Olympic flame,

but a safety flare.

Flames at the end of a long, thin pipe – which at times can be seen from great distances and is an important part of our safety systems – are indications that the refinery is operating in a completely safe state.

The processing of crude oil also generates gases, that we use to fuel the process furnaces. This saves energy. Large volumes of gas can however still arise if production is paused, or when systems are started or stopped. These are then controlled and safely led to the flare to be burned. This can result in meter-high flames, which may look threatening, but actually signify safety.

Naturally we adhere to all environmental regulations and statutory provisions if we do have to "flare off".

Get in

touch

Moorburger Str. 16

21079 Hamburg

Germany

📞 +49 40 76 63 0

📨 info@HOLBORN.de

Please send applications directly via the online form for the respective job advertisement on the careers page.